Raw material and Equipment selection, Budgeting and Purchase Orders

We strive for local content during the selection of raw materials, equipment and assets in our pursuit to support local economy and needs. With a global network of raw material suppliers, we are successful in achieving local content and thus present you our best solution.

Based on our theoretical mix design and the laboratory tests, we can provide you with a quotation of the corresponding investment. This quotation embodies purchase of raw materials, deployment of personnel and equipment and all related logistics. From this point, adjustments of the requirements from your side are not free of charge anymore.

Simplified overview of custom made products

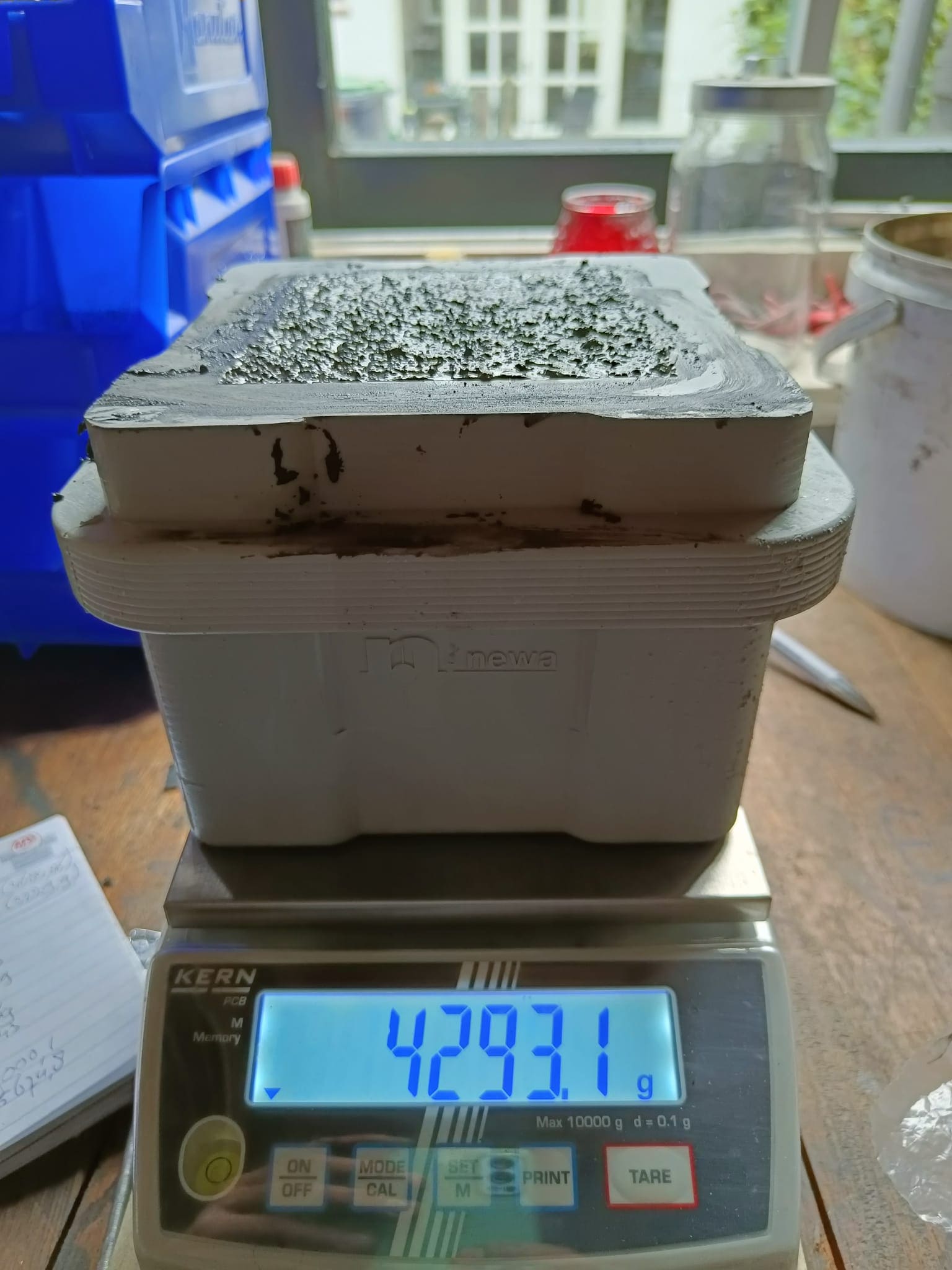

Design and engineering of ballast slurries and heavy concrete:

- In a density range from 2,350 kg/m3 (146.71 lb/ft3) up to 4,300 kg/m3 (268.44 lb/ft3) for pumpable ballast products – product densities over 4,300 kg/m3 are achievable, depending on the project conditions;

- With a slump (according EN12350-2) up to 210 mm;

- With a flow (according EN12359-5) up to 620 mm;

- With a slump flow (according EN 12350-8) up to 750 mm;

Supporting activities

Besides Design, Engineering and Installation of ballast slurries and high density concrete, we are also active in minerals trading. We have access to a wide range of Fe based minerals and metals (magnetite, hematite, reclaimed iron oxides, blast furnace slags) produced and sourced globally.

GBC offers a range of aggregates and minerals, to produce for example:

a) High density or heavy concrete in range of 2,600 – 5,100 kg /m3 (162,3 – 318,4 lb/ft3)

b) Loose bulk ballast in range of 1,800 – 3,600 kg/m3 (112,4 – 224,7 lb/ft3)

c) Solid returnable ballast in range of 2,600 – 5,500 kg /m3 (162,3 – 343,4 lb/ft3)

Our goal is to match demand and supply. If it’s not part of our portfolio, we will make it part of it.