Raw material supply for prototype counterweight bucket

Project scope

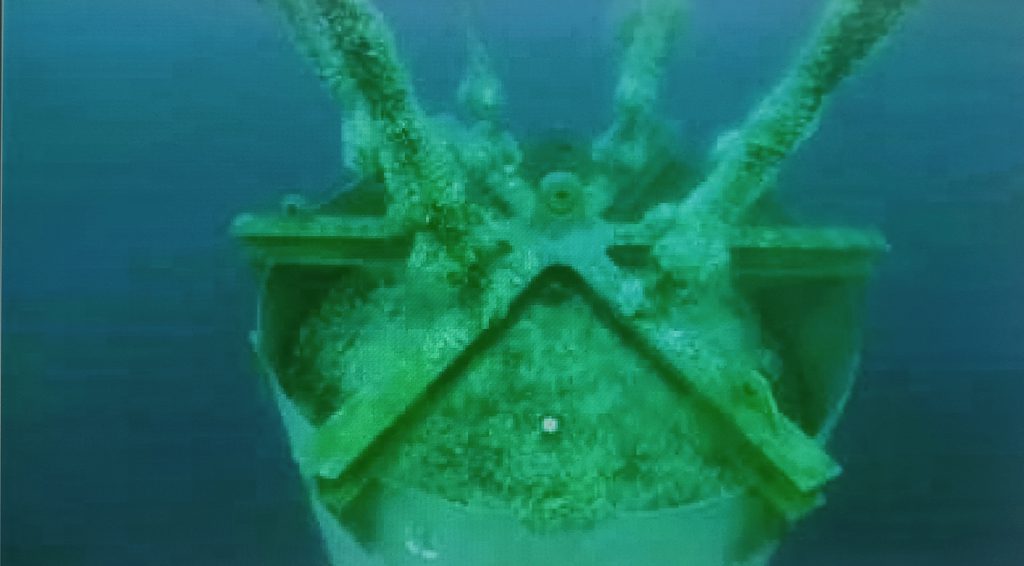

CNR-INM (Consiglio Nazionale delle Ricerche | Istituto di Ingegneria del Mare), commissioned by Saipem SA, performs a range of tests on a scale model counterweight submerged in the Mediterranean Sea. The tests are part of the Saipem’s floating wind turbine concept Hexafloat, a pendulum concept with a submerged counterweight hung to the floating foundation of the turbine. What is the best way to handle 0-8 mm magnetite for installation in a steel bucket? What is effect of marine conditions on the steel structure and the ballast infill? How is easy is the material to decommission after 1 year being submerged in sea water?

Conditions

The steel bucket is placed on the ground at the premises of a Naple’s shipyard. The ballast will be installed by feeding the material directly out of a big bag into the structure, using a forklift to handle the big bag. The counterweight is attached to a buoy with mooring lines and installed in the Mediterranean Sea. After 1 year the structure will be decommissioned.

Milestones

- Supply of 7 tons magnetite 0-8 mm in bulk bags

- Raw material selection and supply and installation assistance

- Dry bulk density 3,100 kg/m3 (193,53 lb/ft3)

- Installed weight 5.7 metric ton

- Manual installation